Can You Cut Aluminum With An Angle Grinder?

Angle grinders are powerful and robust tools that can cut through some of the toughest materials. Its unique ability comes from its grinding wheels, which are its individual and sharp cutting blade.

However, just like any other tool, there have to be a few limitations to this too. So, can you cut aluminum with an angle grinder? Yes, but let’s dip into the subject a bit more to get the whole picture. With our thorough research, we can unveil the limitations and potential risks too.

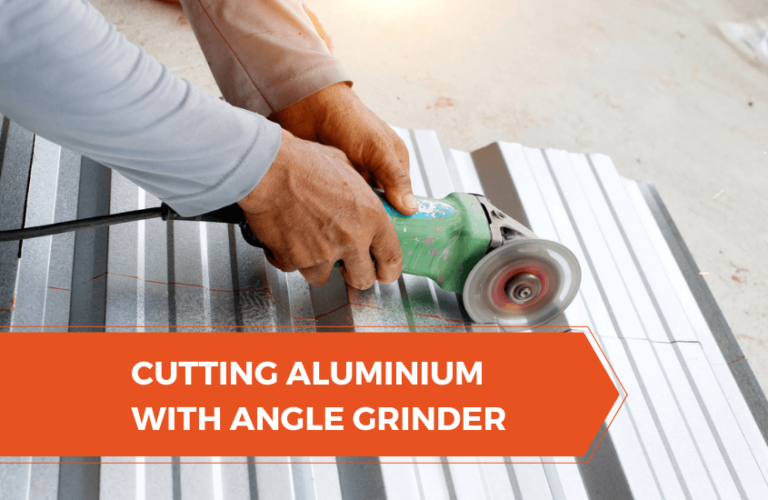

How To Cut Aluminum With Angle Grinder

The trick lies with choosing the accurate disc for the angle grinder. It would help if you didn’t use broken angle grinder discs for aluminum. These could do more harm than good to your aluminum. The disc could shatter, and the fragments could damage the environment and material during use. It’s incredibly hazardous to you and the aluminum. Here’s how you can guarantee that your aluminum cut will come out clean.

1. Attach The Grinder Properly

You must ensure that the bolts are tightened and adequately attached to the grinders. Moreover, these have expiration dates, too, so you must replace the components as required. Grinders can often accumulate dust and moisture, which can lead to severe damages as well.

2. Don’t Force It

If the grinder resists driving into the aluminum, give it a scan before forcing it again. If the angle grinder is overloaded, it might cause such issues, along with sparks at an uncontrollable rate. To eradicate this situation, you can angle the grinder so that the device develops optimized speed and hence, cuts through the aluminum gently. If you turn the tool at 90 degrees, you will see accurate results without unwanted breaks or bends.

3. Cut through

If you stop the grinder midway, unexpectedly, it might stick to the aluminum. Once you’ve begun cutting through the aluminum, make sure that you see through it. Once you’ve chopped off the needed portion, allow the tool to cool off. This falls under safety issues, and the grinder will be too hot to touch; therefore, don’t skip this step.

Best Angle Grinder Wheels For Aluminum Cutting

Dealing with such metallic substances can get tricky. The best part about angle grinders is that you can use them on many kinds of metal elements such as sheet metal, steel, iron, pipes, bolts, and of course, aluminum.

However, keep in mind that you must opt for an abrasive metal disc to cut through these components. Before using, ensure that you have secured the disc on the angle grinder perfectly and secured it. Place the aluminum on any flat surface and secure it along the C-clamp. To be even more specific and to cut with precision, you can mark a straight line on the material where you want your desired cut. Once that’s done, you must put on all the necessary safety gear.

Begin cutting the aluminum with the lightest pressure initially and keep a steady position and hand while doing so. Generally, you might not need intensive pressure as the discs are pretty thin, and so is the aluminum. Therefore, forcing either of the objects will only push your luck and result in more kickbacks.

Furthermore, when you’re done with chopping the aluminum, you can remove and disc and utilize a flapper disc to smoothen out the edges if needed.

Best Angle Grinder For Cutting Aluminum

Let me introduce three of our top options that are affordable yet, high quality. The results that you can achieve with these are pretty vast and standard if you always want your work a specific way. Fortunately, these are all tested and approved; thus, they are highly capable of performing with unparalleled results.

1. Makita 9557PBX1 4-1/2″ Paddle Switch Cut-Off/Angle Grinder

Equipped with a robust 7.5 AMP motor with high output, this compact tool comes with a small barrel grip diameter and extra-large paddle switch for extra comfort. It comes with a labyrinth construction seal that protects the device and motor against debris and dust.

It is constructed with one general-purpose turbo rim diamond blade-A 94552and features an easy lock on and off for consistent operations. One of the best specifications is that it arrives with a zig-zag seal to provide protection against debris and dust and thus, helping with extending the life term of the tool.

Pros

- Comfortable design

- Debris and dust-free features

- Versatile operation

- Lightweight

Cons

- It takes longer to cool down

2. DEWALT DCG413B 20V MAX Brushless Cut Off Grinder

The Dewalt comes in four styles; safety goggles, cordless starter kit, 20V brushless 4-1/2 grinder, and 20v 4-1/2″ grinder. The best safety feature is that the brakes are highly efficient and stops within 2 seconds or less, especially when there are signs of kickbacks, bind-ups, and stalling.

It includes E-switch protection without a volt release functionality and two actions needed to activate the device.

Pros

- Safest to use as the trigger switch is needed to restart the tool

- Ergonomic design

- Portable

- Bang for the buck deal

Cons

- The batteries heat up during use

3. AVID POWER Angle Grinder 7.5-Amp 4-1/2 inch with 2 Grinding Wheels

Avid is a highly powerful grinder with a 7.5 amp motor, 900W maximum output, and speed of 11000 RPM. It can withstand even the toughest of applications and is easily portable too. Its compact, lightweight, and slim ergonomic design is made to eradicate fatigue during work hours and heighten comfort for professional usage.

Moreover, it also includes a protective cover with a portable grinder to maximize protection and enhance durability. Users especially love that these come with safety triggers that are easy to operate, and the powerful motor can efficiently cut, grind or sand.

Pros

- It comes with a spindle lock

- Comes with one user manual, one flap disc, one side handle, one spanner, two cutting wheels, two metal grinding wheel, and one 7.5 amp 4 ½ inch angle grinder

- Application is made incredibly easy with its three-step installation process

- Easy to use and ergonomic

Cons

- The construction could be better

More than anything, it’s necessary to focus on choosing the right tool for this job. , driving any device at hand wouldn’t guarantee a clear finish. Therefore, our recommended angle grinders can be operated on aluminum risk-free, precisely while keeping the user safe.

Safety Precautions For Cutting Aluminum

Undoubtedly the best way to cut aluminum with an angle grinder has been illustrated but, what about the safety measures? Angle grinders are electrical tools with hefty and powerful motors. Dealing with their sharp and defined blades alone can be highly intimidating. Therefore, to work in a risk and hazard-free environment, users must follow all the safety protocols and avoid accidents along the way.

Here are a few tips on how you can maintain these safety standards.

1. Protective Gear

You must purchase protective gear before working with such tools are goggles, correct clothing, wear gloves, and earplugs. The main motto is to protect your hands, lungs, ears, and eyes. Therefore, you must choose the proper outfit and gear to avoid coming into contact with the sharp and hot grinder edges.

2. Avoid Wet Areas

Angle grinders must be used in arid areas. When misused, the machine could slip and slide, which, when combined with the electrical output and water, can cause severe damages.

3. Fire Extinguishers

It’s just another preparation to face any fire risks and hazards. Thus having a fire extinguisher near the workspace is mandatory.

4. Remove Accessories

The aluminum cutting disc angle grinder can catch everything that’s in their way and quite seamlessly cut through them too. Therefore, before using the grinder, you must remove any string, bracelets, earphones, and jewelry for utmost safety.

5. Stay Away From Flammable Components

Before working with angle grinders, you must eradicate all flammable items from the work area, such as paper, oil, diesel, and gasoline. These can act like ticking time bombs and could cause extensive fire outbreaks. As angle grinders produce sparks, these substances could easily ignite a fire if nearby.

6. Power Cables

Be extra careful with the angle grinder’s cables and ensure they’re behind you and the device, so you don’t accidentally cut them. This will also prevent you from tripping on the power cable as well.

7. Decluttering

Before working with such powerful tools, it’s better to declutter the work arena and rid yourself of unnecessary toolboxes, cables, and devices. Not only will this make a comfortable environment for you to work in but, it’s also extremely safe.

Conclusion:

So, can you use an angle grinder to cut aluminum? Heck, yes!

One reason to stay alert during the complete ordeal is that angle grinders can chop off almost all materials with their powerful motor and functions. This increases their chances of kickbacks and injuries too.

That said, angle grinders are technically a God sent, as your tasks can be made tenfold easier and quicker. If you can keep a few points in check during working with angle grinders, it can deliver top-tier results and that too within mere minutes.

FAQ:

Do You Need A Special Grinding Wheel For Aluminum?

With the right grinding wheel, it can be done relatively quickly. Special grinding wheels are made specifically for aluminium, designed to cut through the metal quickly and efficiently. If you’re doing a lot of aluminium grinding, it’s worth investing in one of these specialized wheels.

What Is Needed To Help The Process Of Grinding Aluminum Go Faster?

The speed of the grinding process can be increased by using finer grits, more water, and more pressure.